Detachable Container Houses VS K-type prefab house

The building industry has seen some pretty radical changes over the past several years, and that is primarily due to the fact that there have been an increasing number of people seeking a more practical, efficient and cost-effective approach for building or constructing a house. In a broad range of new housing, balance emerging ecological benefits and resource efficiency will make the detachable container houses and K-type prefab houses get popular. As much as they are new and emergent, these two forms of housing present some benefit and some burden not only in terms of flexibility and affordability. They are each qualities that range from strong structural stability to large ecological footprint, serving different purposes. This paper claims to explore characteristics of comparison & contrast between the two as regards exposing relative strengths and weaknesses. In this context, a comparative study is carried out in order to provide relevant information on which housing solution may be more appropriate for specific applications, based on the three key factors of sustainability, economic viability and functional feasibility.

Structure and Materials

On the fundamental level, detachable container houses are container homes created from steel shipping containers which have been adapted for residential or business use. Containers have an inherent sturdiness, given that they've been made to sustain tonnes of load and bad weather, apart from stresses that accompanied seafaring. And just this remarkable strength makes it great material for building sturdy and safe homes. Because these containers have a steel structure, they are incredibly resistant to environmental stresses including hurricanes and earthquakes; thus there is an impressive durability and strength guaranteed. As the aforementioned reasons suggest, these house containers suit the places that can expect such conditions. They are more resistant to many of the common issues facing the historic buildings like termite damage and wood rot—which makes them a more durable choice.

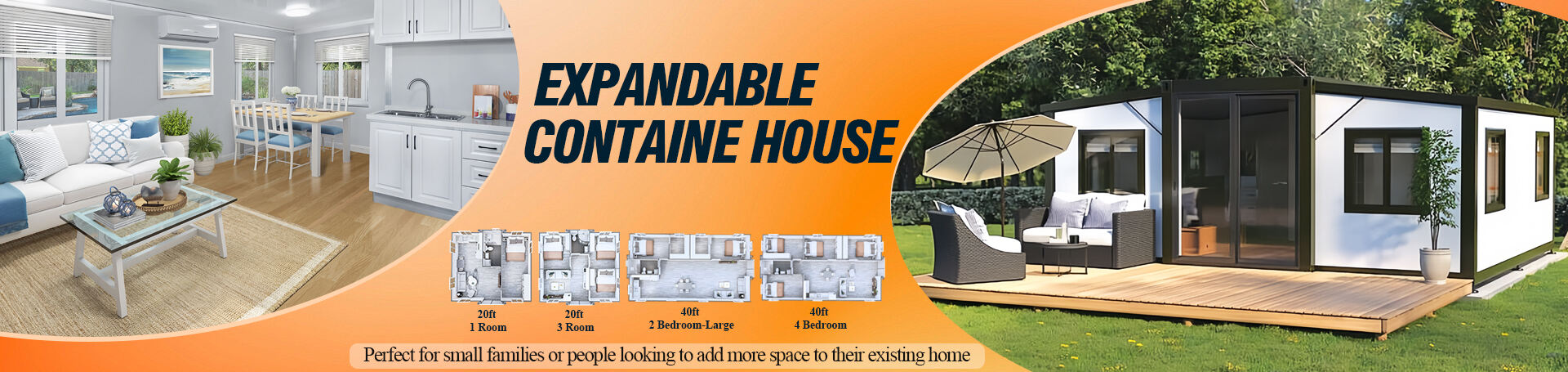

Apart from the most modular nature of container houses, these units can be very well customized. From a single, modular crate to sprawling, multi storey homes, homeowners are able to stack, us, and repurpose containers. Anyhow, apart from beyond all this potential, it is still immensely invasive to convert shipping containers into proper living spaces: insulation, windows and doors and thousands of other communications need to be installed which destinedly lifts the price of such projects.

In K-type houses, building construction technology employs light steel frames combined with sandwich panels as wall and roof materials. Such panels are usually made of a substance such as EPS, rock wool or polyurethanes that can give these products incredibly effective thermal insulation and soundproof characteristics. Such like material help in energy efficiency of the buildings and make comfortable living conditions. The light steel structure provides substantial freedom in design which is not possible in the rigid format of container houses. To minimize construction time and labor costs, K-type prefabricated houses are made with components that can be easily moved to the site for assembly.

K-type manufactured homes will be light weight in general and also have less difficult erection, they are really more flexible with regards to a potential for layout change and design. This basically means they look good from the outside, but in actuality have no strength or rigidity over container houses. The steel of K-type houses is light, and while it is a sound structure, its housing does not possess the same solid construction and ability to withstand elements as heavy-gauge steels used in shipping containers. For many applications, particularly with less severe conditions not requiring the more durable M-type prefabricated house, the K-type offers positive advantages in flexibility and ease of assembly making it a popular option for use in residential and commercial construction.

Installation and Transportation

Container houses and large parts of detachable K-type prefab house highlight intact transport assembly super easy installed, it greatly simplified the construction work. Container houses, for example, rely on standardized shipping containers available in sizes such as 20 or 40 feet long as their main building component. Since they were standardized, they can be easily shipped using existing global shipping infrastructure. The containers also boast other logistical perks as they can be easily packed, shipped, and delivered just about anywhere. When on site, they can simply be stacked and joined together to form your installation. It would also, apart from speeding up construction time, remove a good deal of the labour expense involved in more conventional methods of building.

The K-type prefab houses are made simply to have even much more effective and easy assembling therefore equals in terms of their transportation & installing. These are light steel frames and sandwich panel components of these houses which have been designed to be lightweight and compact in order to enable easy movement at a lower cost of shipping. They are built to the millimeter so that when it is being assembled, all components fit in place seamlessly. The panels and frames are then sequentially assembled to the foundation, where this whole process can take as little as a couple of days. Not only does this reduces the environmental cost through less site waste and disruption, it makes assembly cheaper and faster.

Both had become modern construction efficiencies, scalable & adaptable solutions working across several geographies and climates. Each is also literally or figuratively modular in nature, allowing for quick deployment but also allowing for future expansions or reconfigurations to be built with ease. Hence, in scenarios where the speed of assembly, low level of disturbance as well as design flexibility is a necessity a detached container house and K type prefabricated house become an interesting proposition.

Lifespan

Either from an economic or environmental point of view, life span is one of the most important variables for a building. Steel shipping containers, which are the basis of container houses, are much more durable than other buildings of similar type and they can withstand generations of use without major failure if properly maintained. This steel type for such containers is to introvert the adversities of maritime shipment circumstances, like severe temperature conditions and that is why it is quite suited for the construction application. Its natural resistance to insect pests, as well as to fire spread, can lead to an increase in building longevity. Other than that, because you would be painting the container regularly and preventing any rust from appearing on the surface of the shipping container house, it will last for a very long time which makes this option quite sustainable.

K-type prefabricated houses on the other hand are usually waterproof but should also have a shorter service life than steel container house when it comes to durability. K-type houses are primarily constructed using light steel frameworks and insulation sandwich panel. Although efficient and versatile at the time of building, these materials can be extremely vulnerable to anything mother nature might throw their way. In other words, if the light steel frames are untreated or exposed to humid and salty air like in a coastal area it is prone to corrosion. Protective coatings and protective inspections against damage are the used factors for the standard maintenance against deterioration for increase their service life. So based on these terms, the K-type pre-fabricated house remains to have a comparative advantage in consideration of energy conservation and reduction of construction waste. That makes it more in line with sustainability. However, the need for ongoing maintenance and potential exposure to environmental conditions must be planned and designed around where their useful life and sustainability is optimized.

Comfort, Insulation, and Soundproofing

Sound insulation and its cushion of comfort in home. Generally, one of the bigger challenges with container homes is insulation and soundproofing because they are wall to wall steel. Still, they can be very comfortable and insulated which is also great as long as it is properly modified. And because they're newer, soundproofing may require added expenses to achieve a level of comfort similar to regular homes.

In general, even at the beginning stage of construction, K-type prefab houses have better thermal and sound insulation quality because the sandwich panels used in their construction were usually made to improve thermal insulation and noise control. This just means they can acclimate to either warmer or cooler weather without too much trouble.

Cost and Economic Efficiency

Cost-effectiveness is always an inevitable aspect in the choice of these two classes of houses. Container houses can often be built relatively cheap because the fundamental structure combines preused shipping containers, which are typically less expensive. The cost depends on how much of a finish and what type of changes are required.

Mainly the construction and labor have influence on K-type prefabricated house prices. This would reduce overall project cost to less than half, due to the speed of assembly requiring less skilled labor. Depending on what materials are to be used to update the insulation and look, that cost will go up.

Environmental Impact and Recycling

From an environmental saving perspective, both container and traditional houses have their advantages. These sorts of home building require some sort of upcycled shipping container that not only helps to reduce waste and demand for new materials but they are also born to be eco-friendly. But it takes a fair bit of energy to modify information, if the data requires significant alteration.

And another reason because K-type prefabricated houses are much eco-friendly by nature due to the recyclable materials they are formed with. This process also creates less waste than in other forms of construction, as the parts are pre-measured and cut.

Application Scenarios

Ultimately, the difference: K-type prefab house or detached container house: — is often a matter of WHAT will they be used for? Deployable container homes are typically beneficial in emergency housing, workplaces, and workshops because of their strength and security features, particularly for temporary or semi-permanent installations. These are also used for residential complexes in contemporary urban centers which prefer the industrial look.

K-type prefabricated houses are suitable for many fast and different design areas. Thanks to its flexible comfort conditions, this type of house if used in living communities, schools and hospitals.

EN

EN

FR

FR DE

DE AR

AR TR

TR ES

ES